Secret Project Glow Cloud (Embroidery)

All of the stitches in the wearable circuit elements of Secret Project Glow Cloud were simple running stitches, which I tried to keep as consistent as possible. The real embroidery work for the Glow Cloud was concentrated in two decorative elements: the Welcome to Night Vale logo in front of the light sensor, and the cloud design in front of the light circuit.

Putting the “Cloud” in “Glow Cloud”

I waited until very, very late in the project to work on the most stylistically important element - the overlay for the LEDs which would make the whole thing be, recognizably, a cloud, instead of just a bunch of weird-looking lights. I also needed to stuff the space between the overlay and LEDs with some kind of diffusing material, in order to have the LEDs each light up a region of the cloud, rather than appearing as point sources within a dark space. Perhaps because the deadline was looming very close when I began on it, this is the only component which wasn’t taken apart and reworked at least once; the cloud in the final design is the first and only cloud I made.

The cloud’s borders had to be outside of the edges of the outermost LED circuit boards by at least about a half an inch. Rather than try to do anything fancy to calculate and trace it, I just laid down a scrap of linen over the canvas with the LEDs sewn in and traced a pattern that seemed vaguely cloudlike and didn’t overlap any PCB. I ran a simple outline stitch over the pattern I’d traced, then ran some hot glue around the backside of the design I’d stitched in, hoping that it would keep the delicate linen from fraying so much after I cut it. (Thanks to Bob Baddeley for this suggestion; it worked a treat.)

cloud edge pun here

Coming together!

Once I had the cloud mostly in place, I stuffed some batting in until it looked about the right amount of diffuse, then closed it up and added a few other securing stitches where I had noticed some batting about to escape. Finally seeing this element come together was really wonderful, and I felt for the first time like I might make my January 16, 6pm deadline.

Lights out, ready for action!

Logo: Trace, Outline, Fill, Swear, Decompose, Fill, Outline, Fill, Outline

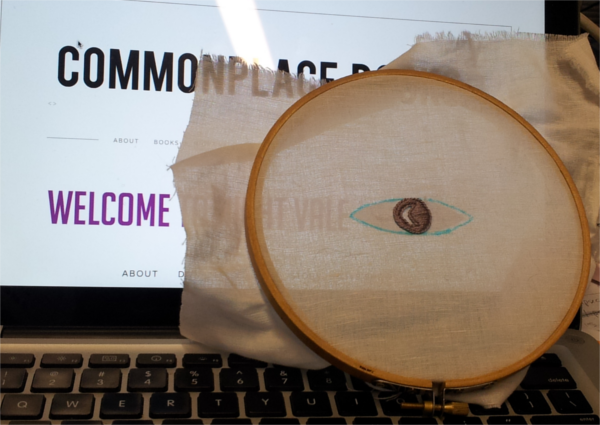

Pretty good for eyeballed, right?

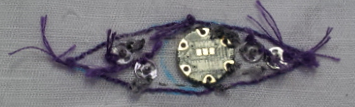

My general plan for the light sensor and logo was to sew the light sensor, facing forward, into the back of some lightweight linen. I’d connect the four pins of the light sensor to some small metal snap posts, then sew some snap sockets into the canvas onto which I planned to sew the rest of the circuit. I would use an adapted open satin stitch for the fill elements in front of the snaps, so that the snap posts themselves wouldn’t be rendered unusable by the embroidery floss I was using for the fill.

The front of the in-progress Welcome to Night Vale logo, with visible puckering of the fabric where the fill of the sclera element is completed.

The other problem probably would’ve been obvious to anyone with any great facility in the third dimension. (This obviously does not describe me.) With the light sensor in the way, how in the hell was I going to do the fill for the iris? Since the light sensor was off-center, it may have been possible to get a needle in for the left side, but it would’ve been impossible to complete the right side. The design was a dead end, unless I wanted to undo all of the sensor work I’d done and redo it. I decided that if I was going to bother doing that, I should do a better overall design.

High-tech!

For the second iteration, I just made a patch that vaguely resembled the Welcome to Night Vale logo, leaving the moon design in the middle unfilled. (The need to use a lightweight linen and not fill in the moon was driven by the light sensor I intended to populate behind it - if too many opaque elements were included, the elements obscuring the light sensor wouldn’t admit enough light, and the light sensor would be useless.)

I began by tracing my already-poorly-traced first iteration onto a fresh piece of linen. I also worked from the inside out this time, as I was concerned that I would have trouble with testing and placement since I was keeping the light sensor and the patch disconnected until late in the assembly process. I first ran over the outlines of the moon and iris elements with an outline stitch, then filled the iris in with a horizontal satin stitch. I found the end result unsatisfactorily non-circular, but my friends (who were all, by this point, heartily sick of me tearing parts of this project apart and starting over) convinced me that it was good enough for government fan work. After spending a silly amount of time trying to satin stitch under my outline stitches in the iris, I decided to do the fill stitch first for the sclera.

About six hours in.

This took forever.

A look at the fabric sandwich.

All sewn up.

All Together Now

Once both the cloud and the Night Vale logo were sewn onto the linen, I realized I really needed to get the rest of the linen secured to the canvas before I could take everything out of the hoop without worrying about destabilizing the alignment of the fabrics. I did a quick running stitch in a rectangular pattern around three of the edges to keep everything in place. I had to leave the top open so I could run the power cable out of it – I really wish I had had time to make this more elegant.

By the time I had all of this together on the same piece of fabric, it was pretty close to time to go line up for the show. I laid the canvas-components-linen-components-batting sandwich out on a spare purple long-sleeved T-shirt, did a quick fold of the edges, pinned everything in place as best I could without sewing the shirt to itself, and sewed as fast as I could. These two steps were the only place in the project where I would’ve trusted my machine sewing skills, but unfortunately by the time I was ready to do them I was 2,000 miles away from my sewing machine. Hand sewing it is!

Every stitch lovingly made by hand.

At the show, someone said “I would’ve just stuffed a bunch of Christmas lights in there.”